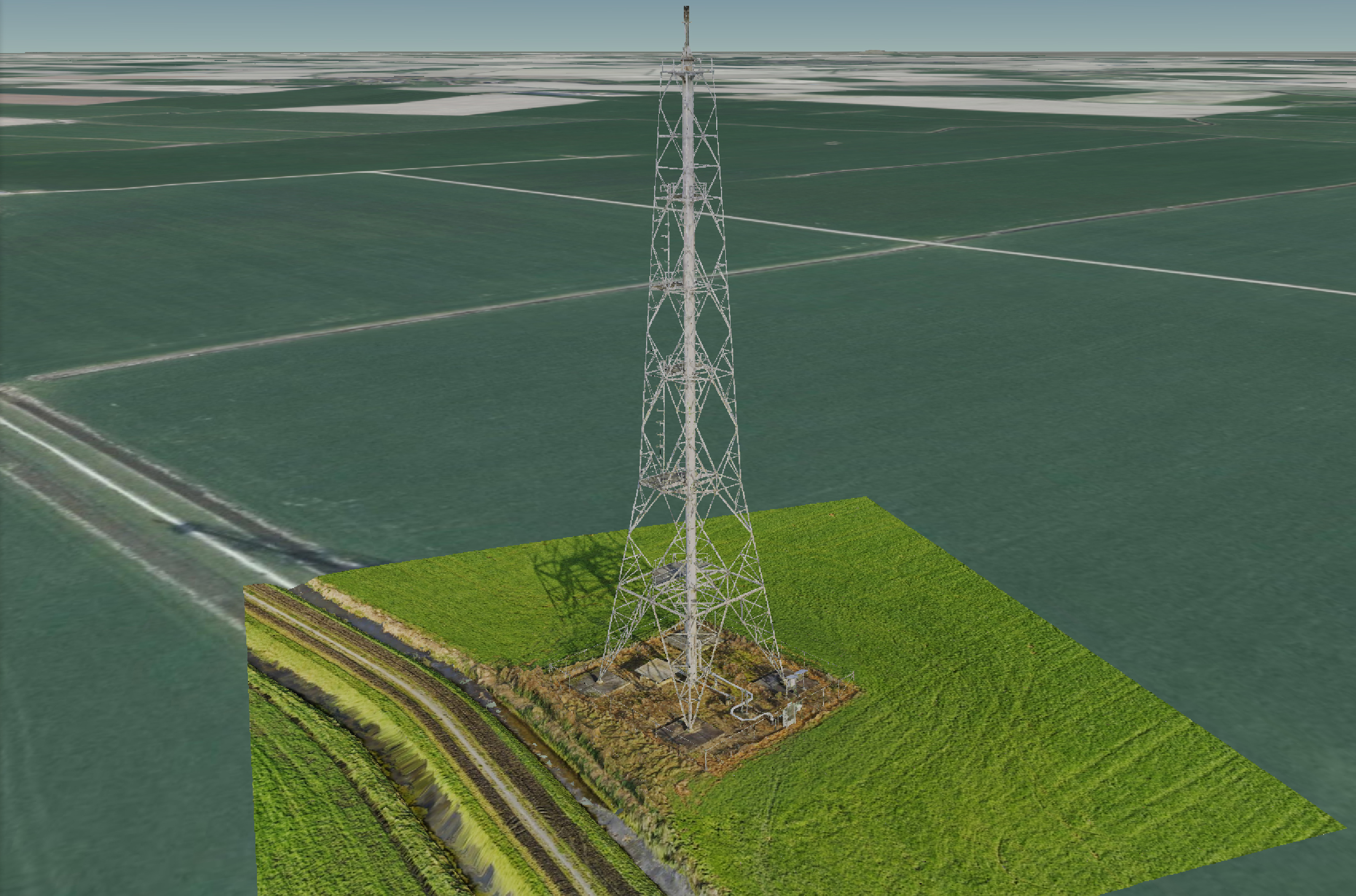

Use cases

See which industries can profit from unmanned, safe and fully automatic inspections.Gas flare

apartmentIndustry: Gas flagPurpose: Detect corrosion lens_blurImage captures: 1536 query_builderTime to completion: 3 daysA gas flare is vulnerable to corrosion and other defects, but hard to access. With the 3D digital twin it is always possible to revisit the site.

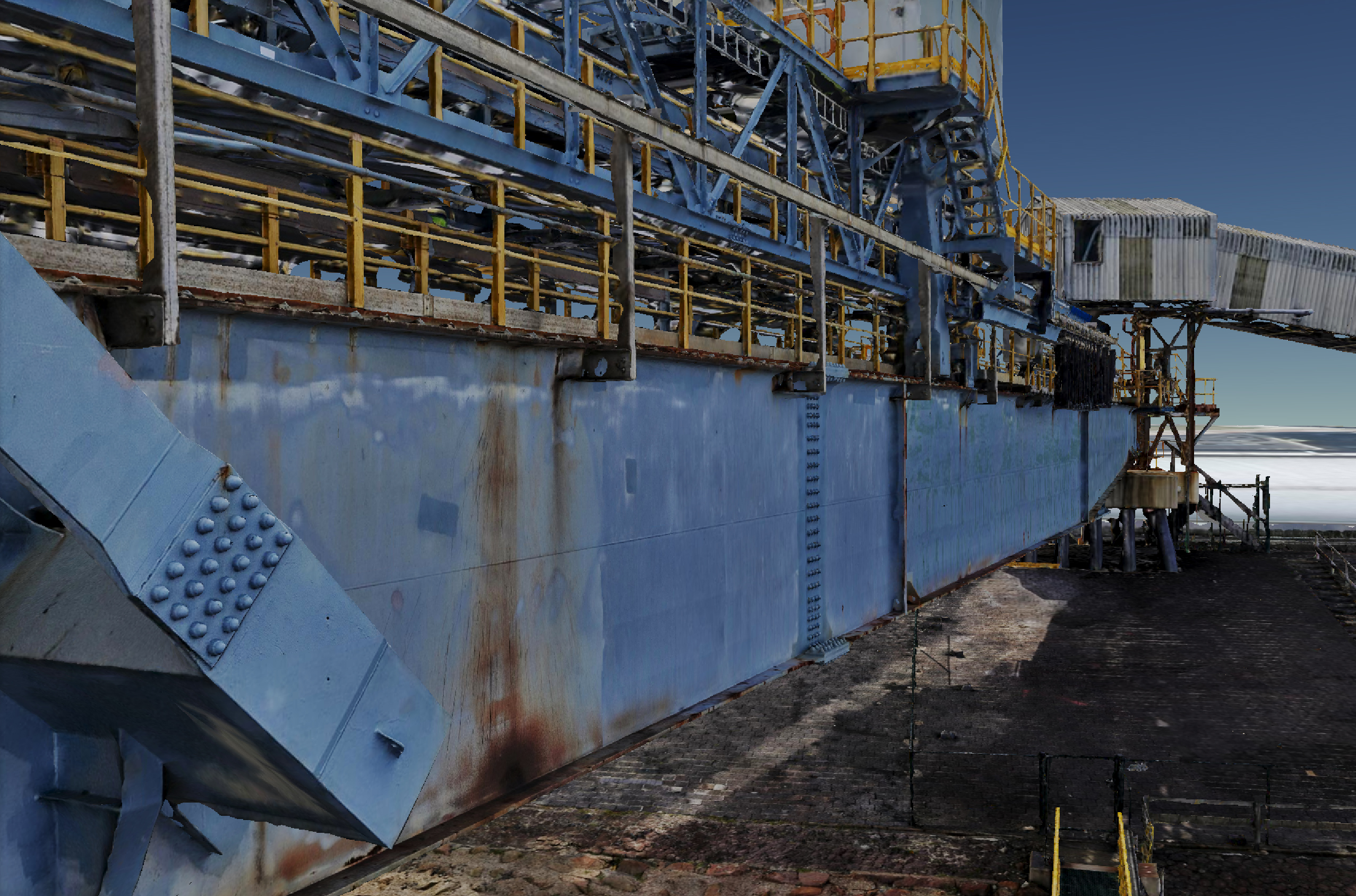

Industrial loader

apartmentIndustry: Chemical flagPurpose: Detect corrosion lens_blurImage captures: 1420 query_builderTime to completion: 5 daysThis industrial loader is prone to corrosion, which is why it was analyzed by our AI algorithms.

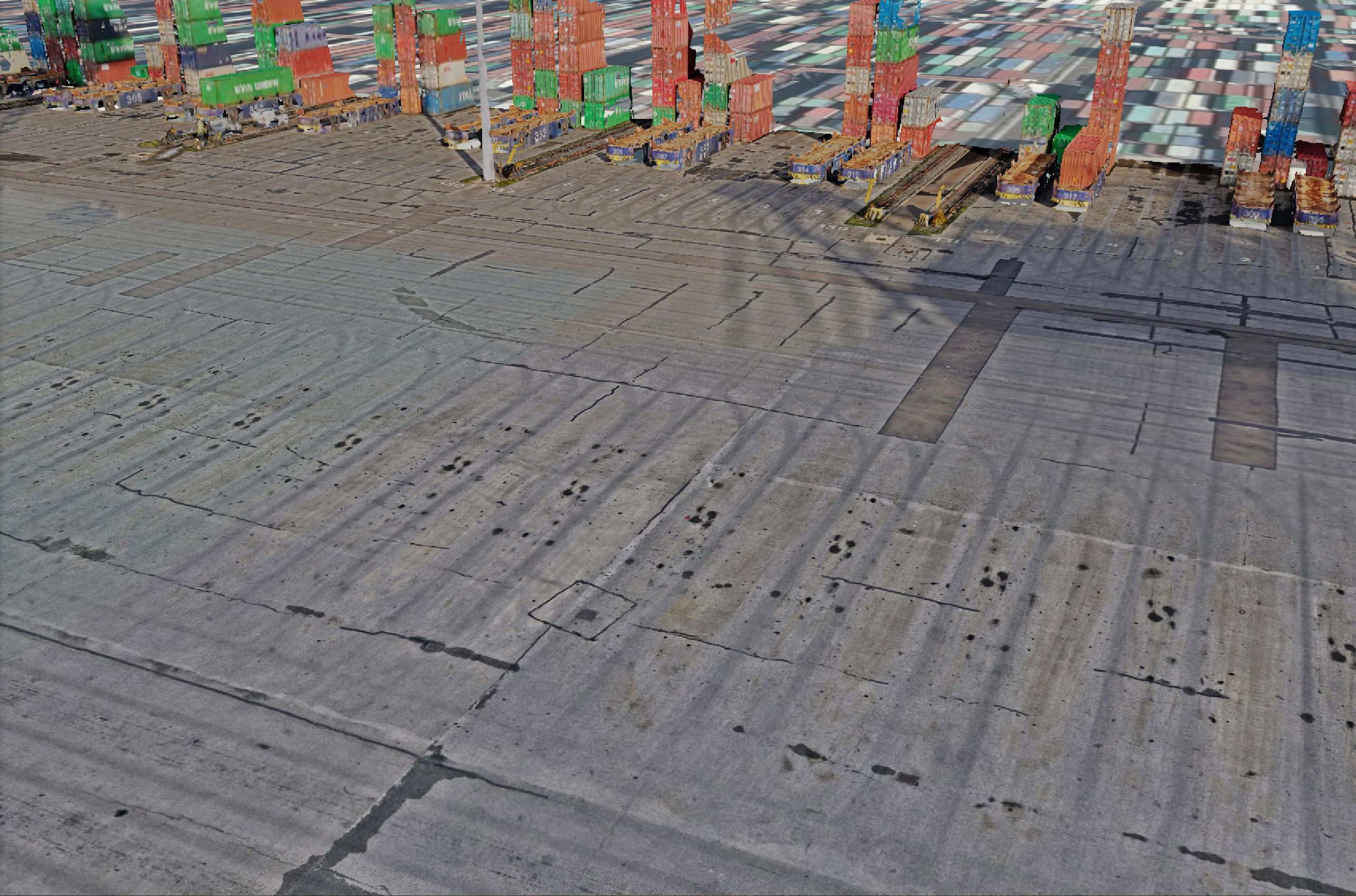

Port terminal

apartmentIndustry: Ports flagPurpose: Detect cracks lens_blurImage captures: 18344 query_builderTime to completion: 15 daysThe conrete in a port is subject to a lot of stress, which in time causes cracks. The 3D mesh of over 2kms of concrete is highly detailed.

Bridge

apartmentIndustry: Infrastructure flagPurpose: Detect corrosion lens_blurImage captures: 1113 query_builderTime to completion: 3 daysThe Algerabrug is a typical steel road bridge, which needs to be checked for corrosion, cracks and other weaknesses. With the 3D model it is always safely accessible.

What is a 3D model?

The 3D models that we create are photorealistic 3D digital twins based on a real-life captured imagery by drones, planes or other unmanned vehicles.

How does the AI work?

We have developed several models that can identify and annotate damages in our 3D models. Ready to use models include defects to bricks, concrete, asphalt and rooftiles. Contact us for tailor-made AI models.

How precise are the 3D models?

The 3D models have centimeter precision. If you're unsure about a tiny detail, you can just pull up the original high-resolution image.

What is the delivery time?

After uploading your images processing takes around a day.